Quick and Reliable Packaging Device Repair Service Solutions to Lessen Downtime

In the competitive landscape of manufacturing, the efficiency of product packaging operations rests on the integrity of equipment. Quick and dependable repair service services are vital in minimizing downtime, which can result in substantial economic losses and functional setbacks. Recognizing the importance of prompt interventions and the duty of professional professionals can change exactly how organizations approach repair and maintenance. Nonetheless, browsing the myriad options offered for repair service services can be challenging. What aspects should services take into consideration to guarantee they are making the right option for their operational needs?

Importance of Timely Fixes

Timely repair work of product packaging machines are critical for keeping operational performance and decreasing downtime. In the hectic setting of production and product packaging, also minor breakdowns can result in considerable delays and performance losses. Attending to concerns promptly makes sure that equipments operate at their optimal capability, thereby safeguarding the circulation of procedures.

Moreover, routine and timely upkeep can prevent the acceleration of minor troubles into major failures, which often sustain greater repair work expenses and longer downtimes. A proactive technique to equipment repair not just preserves the stability of the tools yet additionally boosts the total dependability of the assembly line.

In addition, timely fixings contribute to the longevity of product packaging machinery. Makers that are serviced immediately are much less likely to deal with excessive damage, permitting organizations to maximize their investments. This is particularly essential in sectors where high-speed product packaging is necessary, as the requirement for constant efficiency is vital.

Advantages of Reliable Provider

Reliable provider play a critical duty in ensuring the smooth procedure of product packaging makers. Their competence not just enhances the performance of repair services however also adds dramatically to the durability of equipment. Trustworthy provider are equipped with the technological knowledge and experience essential to diagnose problems properly and execute effective solutions swiftly. This reduces the danger of recurring issues and makes sure that devices run at optimal efficiency degrees.

Additionally, a reliable company offers detailed support, including training and assistance for team on maker procedure and upkeep finest methods. This not just equips employees yet additionally cultivates a culture of safety and effectiveness within the organization. On the whole, the benefits of engaging trustworthy company extend beyond immediate fixings, positively influencing the whole operational process of packaging procedures.

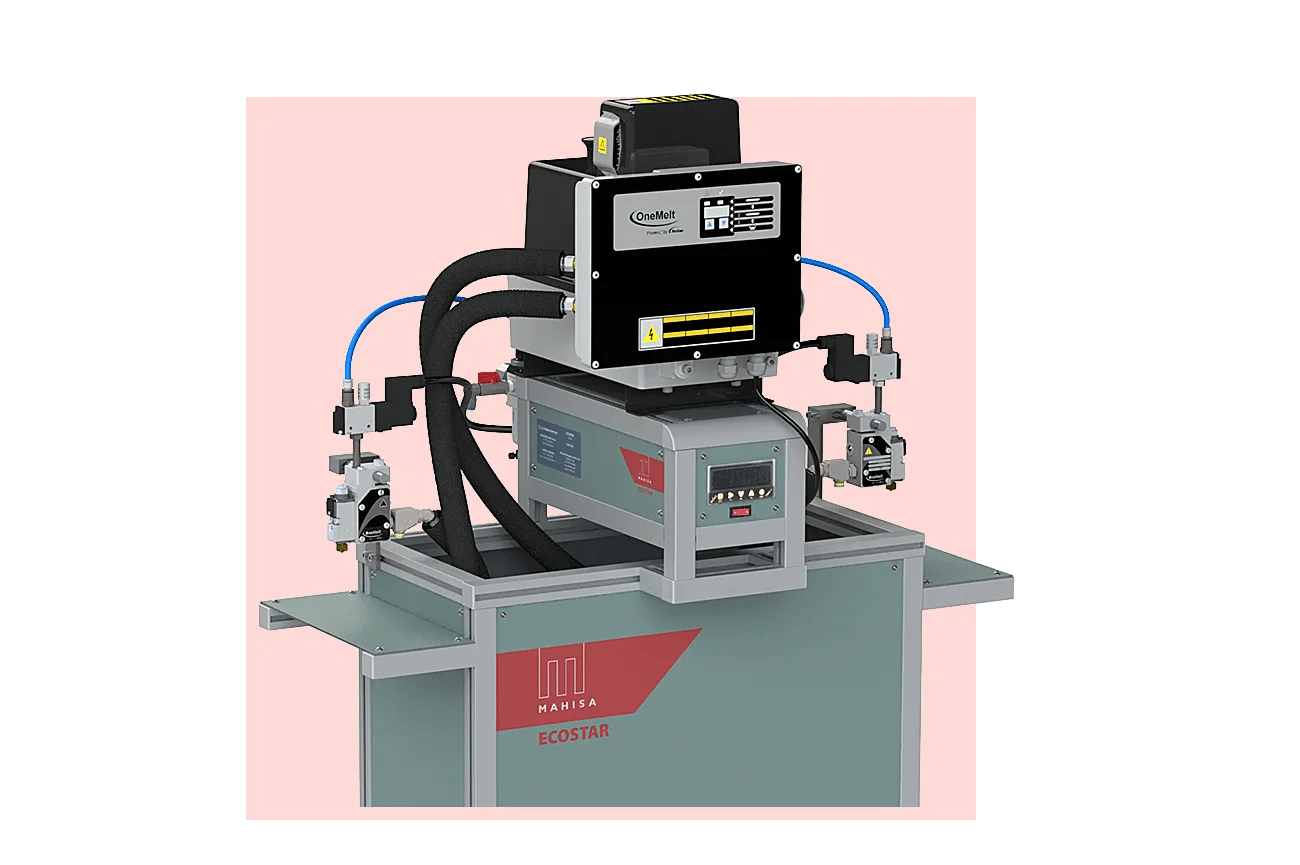

Common Packaging Equipment Concerns

In the world of product packaging procedures, various concerns can jeopardize the efficiency and functionality of makers (packaging machine repair). One more usual concern is imbalance, which can create jams and uneven packaging, influencing item high quality and throughput.

Electrical problems can likewise interrupt packaging operations. Faulty electrical wiring or malfunctioning sensing units may lead to erratic maker behavior, triggering delays and boosted operational costs. Additionally, software application glitches can prevent the equipment's programming, resulting in functional inefficiencies.

Inconsistent product circulation is an additional critical concern. This can arise from variations in item shape, dimension, or weight, which might impact the device's ability to handle items accurately. Ultimately, insufficient training of operators can aggravate these issues, as inexperienced employees might not identify early indications of malfunction or might misuse the devices.

Addressing these typical packaging machine problems promptly is vital to maintaining efficiency and making certain a smooth procedure. Regular evaluations and proactive upkeep can significantly mitigate these worries, promoting a reputable product packaging atmosphere.

Tips for Reducing Downtime

To lessen downtime in product packaging operations, executing a proactive upkeep approach is essential. On a view publisher site regular basis set up maintenance checks can recognize prospective problems before they intensify, ensuring equipments operate effectively. Establishing a routine that consists of lubrication, calibration, and assessment of critical elements can dramatically lower the frequency of unexpected breakdowns.

Training personnel to operate machinery appropriately and identify early indication of malfunction can likewise play an important function. Encouraging drivers with the understanding to carry out basic troubleshooting can stop small problems from triggering significant hold-ups. Maintaining an efficient stock of essential extra parts can expedite repair work, as waiting for parts can lead to prolonged downtime.

Additionally, recording equipment efficiency and upkeep activities can assist identify patterns and recurrent issues, permitting targeted interventions. Integrating advanced surveillance modern technologies can supply real-time information, making it possible for anticipating upkeep and decreasing the danger of abrupt failings.

Last but not least, cultivating open communication between operators and upkeep teams makes certain that any abnormalities are immediately reported and dealt with. By taking these aggressive procedures, companies can improve operational performance and significantly decrease downtime in product packaging processes.

Picking the Right Repair Service Solution

Selecting the appropriate fixing service for packaging devices is an important decision that can significantly influence functional efficiency. An appropriate solution carrier ensures that your machinery is repaired swiftly, efficiently, and to the highest possible standards. Begin by examining the supplier's experience with your certain sort of packaging tools. go to the website A technician knowledgeable about your machinery can identify concerns much more accurately and implement options a lot more rapidly.

Next, consider the solution carrier's online reputation. Seeking feedback from other companies within your industry can provide understandings right into integrity and quality. Certifications and collaborations with identified equipment suppliers can likewise indicate a dedication to excellence.

Furthermore, assess their reaction time and accessibility. A provider who can provide punctual support minimizes downtime and maintains manufacturing flow steady. It's likewise vital to ask about guarantee and service guarantees, which can show the confidence the provider has in their work.

Conclusion

In final thought, the significance of fast and this article trustworthy packaging equipment repair service services can not be overstated, as they play a crucial duty in reducing downtime and making sure operational performance. Implementing proactive maintenance methods and spending in team training more improves the durability of packaging machinery.

Prompt repair work of product packaging machines are critical for maintaining functional effectiveness and lessening downtime.Additionally, timely repair work contribute to the long life of packaging equipment. Overall, the benefits of engaging reliable solution providers expand past instant repair work, positively impacting the entire functional process of product packaging procedures.